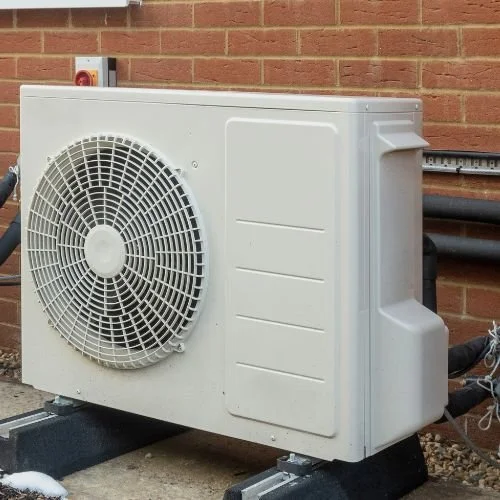

Trane Heat Pump Repair in San Antonio

We serve San Antonio, Helotes, Bulverde, Canyon Lake, New Braunfels, Schertz, and Cibolo

Trane heat pump repair in San Antonio requires specialized expertise to address the unique challenges posed by the region's climate. Professional technicians begin by conducting a thorough diagnostic assessment of the system, identifying issues that may be affecting performance or efficiency. Common problems include refrigerant leaks, electrical malfunctions, frozen coils, or compressor failures. Each of these issues demands a specific approach to repair, utilizing Trane-approved parts and techniques to restore optimal functionality.

Skilled repair professionals leverage advanced tools and technologies to pinpoint the root cause of heat pump malfunctions. They meticulously inspect components such as the reversing valve, which is crucial for switching between heating and cooling modes. Thermostats, capacitors, and fan motors are also carefully examined and tested. In cases of refrigerant leaks, technicians use specialized equipment to detect and repair the source of the leak before recharging the system to manufacturer specifications. Electrical issues are addressed with precision, such as replacing worn wiring or faulty controls to prevent future breakdowns.

The repair process often involves more than just fixing the immediate problem. Experienced technicians take a holistic approach, evaluating the entire system for potential vulnerabilities or inefficiencies. They may recommend additional maintenance or upgrades to improve overall performance and longevity. After completing repairs, thorough testing is conducted to verify that the heat pump operates correctly in both heating and cooling modes. Proper Trane heat pump repair not only resolves current issues but also helps stop future problems, maintaining comfort and efficiency in San Antonio homes throughout the year.

Importance of Professional Heat Pump Repair

Expertise and Skill Requirements: Professional heat pump repair demands extensive knowledge and specialized skills. Technicians must understand complex refrigeration cycles, electrical systems, and mechanical components. They require expertise in diagnosing issues across various heat pump models and brands. Proper training enables them to interpret error codes, perform accurate measurements, and execute precise repairs. Professional technicians stay updated on the latest technologies and repair techniques, allowing them to handle both common and rare heat pump problems efficiently. Their expertise minimizes the risk of misdiagnosis and improper repairs, which could lead to further damage or inefficiency.

Safety Considerations: Professional heat pump repair prioritizes safety for both technicians and homeowners. Certified professionals understand the risks associated with high-voltage electrical systems and pressurized refrigerants. They follow strict safety protocols, using appropriate protective equipment and tools. Proper handling of refrigerants prevents environmental damage and complies with regulations. Professionals can safely diagnose and repair gas leaks, reducing fire and health hazards. Their expertise in electrical troubleshooting minimizes the risk of electrical fires or shocks. By adhering to industry safety standards, professional repairs protect people, property, and the environment.

Long-Term Reliability: Professional heat pump repair contributes significantly to the system's long-term reliability. Experienced technicians not only fix immediate issues but also identify and address potential future problems. They use high-quality, compatible parts that match the heat pump's specifications. Proper calibration and adjustment during repairs optimize system performance, reducing wear and tear on components. Professional repairs often include thorough cleaning and maintenance, which extend the heat pump's lifespan. By restoring the system to manufacturer specifications, professional repairs maintain energy efficiency and consistent performance over time.

Prevention of Further Damage: Professional heat pump repair stops minor issues from escalating into major problems. Skilled technicians can identify underlying causes of malfunctions, addressing root issues rather than just symptoms. Early detection and repair of small problems, such as refrigerant leaks or worn bearings, prevent damage to costly components like compressors. Professional repairs include comprehensive system checks, catching potential issues before they cause breakdowns. This proactive approach saves homeowners from expensive future repairs and reduces the likelihood of complete system failures during extreme weather conditions.

Warranty Compliance: Professional heat pump repair is crucial for maintaining warranty coverage. Many manufacturers require proof of professional maintenance and repairs to honor warranty claims. Certified technicians understand warranty terms and document their work appropriately. They use approved parts and follow manufacturer-specified procedures, preserving warranty validity. Professional repairs provide a paper trail of proper system care, which can be invaluable for future warranty claims. Homeowners benefit from continued protection against defects and premature failures, potentially saving significant costs on major repairs or replacements.

Our Reviews

Our Heat Pump Repair Process

Initial Inspection: The repair procedure begins with a thorough visual inspection of the heat pump system. Technicians examine both indoor and outdoor units, checking for obvious signs of damage or wear. They inspect electrical connections, refrigerant lines, and ductwork for visible issues. The inspection includes evaluating the thermostat and reviewing the system's maintenance history. Technicians also discuss any observed problems or unusual behaviors with the homeowner. This initial assessment provides valuable insights and guides the subsequent diagnostic steps, helping to narrow down potential issues efficiently.

Diagnostic Assessment: Following the initial inspection, technicians conduct thorough diagnostic tests to pinpoint the exact cause of the heat pump malfunction. They use specialized tools such as multimeters, pressure gauges, and thermal imaging cameras to assess electrical components, refrigerant levels, and temperature differentials. Technicians analyze error codes from the system's control board and perform cycle tests to evaluate performance in both heating and cooling modes. This detailed assessment allows for accurate identification of issues, whether they stem from mechanical failures, electrical problems, or refrigerant imbalances.

Repair Recommendations: Based on the diagnostic findings, technicians develop a detailed repair plan. They explain the identified issues to the homeowner in clear, understandable terms, avoiding technical jargon. Repair options are presented, including potential costs and long-term benefits of each solution. Technicians provide recommendations for immediate repairs and may suggest preventive measures to avoid future problems. They discuss the impact of repairs on system efficiency and longevity, helping homeowners make informed decisions. This transparent communication builds trust and allows for collaborative decision-making regarding the repair process.

Repair Execution: Once the repair plan is agreed upon, technicians proceed with the necessary fixes. They follow manufacturer guidelines and industry best practices throughout the repair process. Faulty components are replaced with high-quality, compatible parts. Refrigerant levels are adjusted to precise specifications if needed. Electrical issues are addressed, including tightening connections and replacing worn wiring. Technicians clean critical components such as coils and filters to improve system efficiency. Throughout the repair, they maintain a clean work area and take care to protect the homeowner's property.

Final Testing: After completing repairs, technicians conduct thorough testing to verify the heat pump's proper operation. They run the system through full heating and cooling cycles, monitoring performance parameters such as temperature output, airflow, and energy consumption. Electrical components are re-checked for proper function and safety. Refrigerant pressures and temperatures are measured to confirm optimal levels. Technicians listen for any unusual noises and verify that the system cycles correctly. This comprehensive testing process guarantees that all repairs have been successful and the heat pump is operating at peak efficiency and performance levels.

FAQs - Trane Heat Pump Repair San Antonio

-

Trane heat pumps provide year-round comfort. Skilled local technicians quickly restore performance during extreme weather.

-

Frequent issues include refrigerant leaks, compressor problems, thermostat failures, and electrical faults.

-

Minor repairs may cost $200–$400, while major repairs like compressor replacement can exceed $1,200.

-

Many repairs are done same-day. Emergency services are available during hot summers and cold nights.

-

Yes, most parts are covered up to 10 years if registered. Labor coverage depends on your plan.

-

Absolutely. Fixing faulty parts restores proper heating, cooling, and energy savings.

-

Yes, local providers typically have Trane parts readily available.

-

No, continued use can cause further damage and higher repair costs.

-

Signs include poor cooling, weak heating, rising energy bills, or strange noises.

-

At the first sign of performance decline, before minor problems escalate.